Commercial Catering Services

Commercial Catering Services

Utensils used in the commercial food service industry must be used under a variety of harsh conditions. In addition to high physical properties and high temperature resistance, they must also be resistant to corrosion, including acids in food, proteins and chemical detergents. Typical applications include: fryers, steamers, meat cutters and cabinets.

BMC and SMC are quickly becoming alternative metal materials for catering appliance designers and manufacturers, not only because of the increase in metal prices, but also for many reasons:

Thermosetting materials can be molded and colored, and can be used for various color systems. The designer can form at one time without assembly like metal materials. The manufacturer can provide the customer with a product with a minimum of metal parts, thereby improving cleanliness and reducing the time it takes to clean the appliance. Thermoset composites have many excellent physical and mechanical properties, making them ideal materials for the catering service industry.

Heat resistance: maintain structural hardness at extreme temperatures;

Corrosion resistance: resistance to common in the kitchen, washing supplies and food in the corrosive substances;

High strength to weight ratio, thermosetting parts are 35% lighter than steel parts at the same strength;

High dimensional stability, remains dimensionally stable when exposed to extreme high temperatures.

Case Study

Puzzle

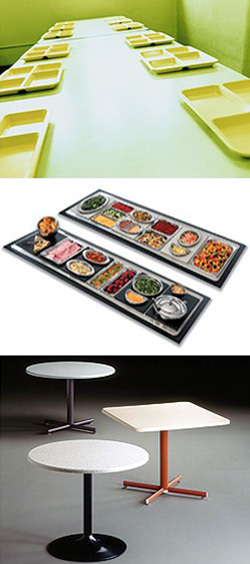

We are a leading professional manufacturer of safe and reliable trays and plates in the food service utensils industry. The food service industry needs to deliver food to customers quickly and efficiently, so materials need to be durable and consistent in appearance. In the traditional food industry, a variety of materials need to be molded multiple times into a multi-layer structure to provide higher load capacity. However, the products produced in this way have a shortened service life.

Programme

With more than two years of thermosetting composite molding experience, we produce food trays with maximum functionality at the lowest cost. The complicated multi-material multiple molding process is no longer needed. These unique processes use different levels of the same material, has been able to meet the needs of different market levels. Two levels of SMC material can meet the needs of different clients, providing excellent mechanical strength, consistency and excellent service life of the product. These products are fully compliant with multiple food industry standards, such as NSF, FDA, etc. Thermoset composites offer perfect solutions, superior functionality and simplified production processes.

Results

Thermoset composites provide a class of materials and longer product life cycles for food service industry products. This leads to a simplified production process, simplified material selection, more cost-effective, higher production efficiency. Most importantly, switching to thermoset materials can save 50% of raw materials and 40% of the total product cost. No matter what kind of customer requirements, this simple production process can achieve the maximum utilization rate of production facilities without the need for production line conversion adjustment.